BRASS, STAINLESS STEEL, CORTEN

Steel System

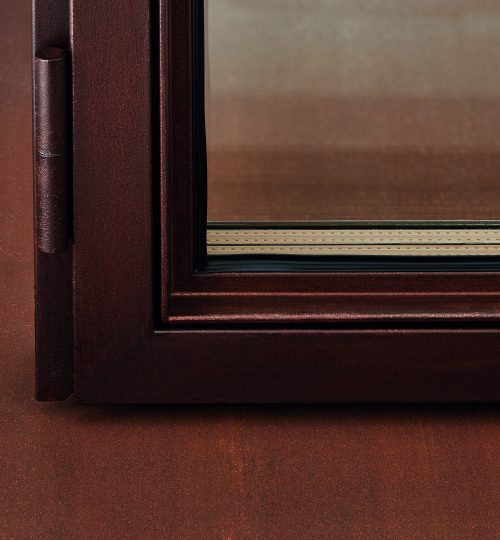

BRASS

The colour and shininess of this alloy, together with the hardness and resistance to corrosion make it a precious and original element for architectural solutions in both old and new architecture. Surfaces in glossy or burnished brass can be an expression of luxury and refinement, or tradition.

When this alloy comes into contact with the air it takes on the richness and the reflections of antique bronze while maintaining its physical properties intact. The natural oxidization determines a level of self-protection that makes the finished product ideal for using in difficult environmental conditions such as maritime settings.

Steel System

CORTEN STEEL

The resistance of corten steel to corrosion is 6-8 times higher compared to traditional steels, as well as featuring double resistance to tensile strength, thus allowing the realization of high-performing fixtures of large dimensions and weight while maintaining the thinness of the sections.

Special alloys obtained with copper, chrome and phosphorus, corten steels have the characteristic of self-protection with a patina on the surface that prevents corrosion from spreading and which gradually takes on colours and shades evoking the passing of time.

Steel System

STAINLESS STEEL

As alloys based on iron, carbon, nickel and molybdenum, stainless steels do not rust if exposed to atmospheric agents, are extremely durable and resistant to corrosion, and need minimum maintenance.

The physical-mechanical features of stainless steel mean that sections can be of reduced dimensions, thus lessening the visual impact of the fixture while enhancing the luminosity of the interiors. With thermal conductivity 10 times lower than aluminium, thermal break elements have a low transmittance value. Special alloys obtained with copper, chrome and phosphorus, corten steels have the characteristic of self-protection with a patina on the surface that prevents corrosion from spreading and which gradually takes on colours and shades evoking the passing of time.

Steel System

GALVANIZED STEEL

The skinpassing of the layer of zinc determines an ideal finish which guarantees better adherence during the painting process; this is carried out with polyester powder coating (oven-baked at 180° C) available in a range of colours, in gloss, semi-gloss and sandblasted versions.